As we approach lambing season, a St Fagans exhibition brings the future of the industry to the fore

WALES is synonymous with sheep farming, but as St David’s Day and lambing season approach the wool industry is facing a difficult future.

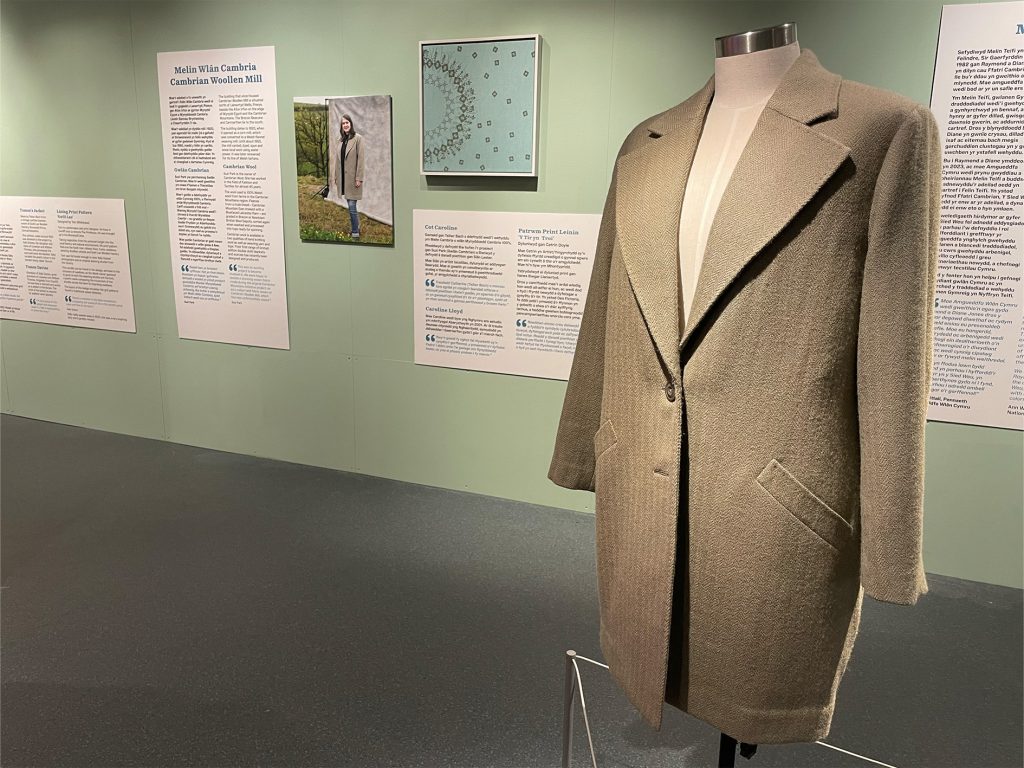

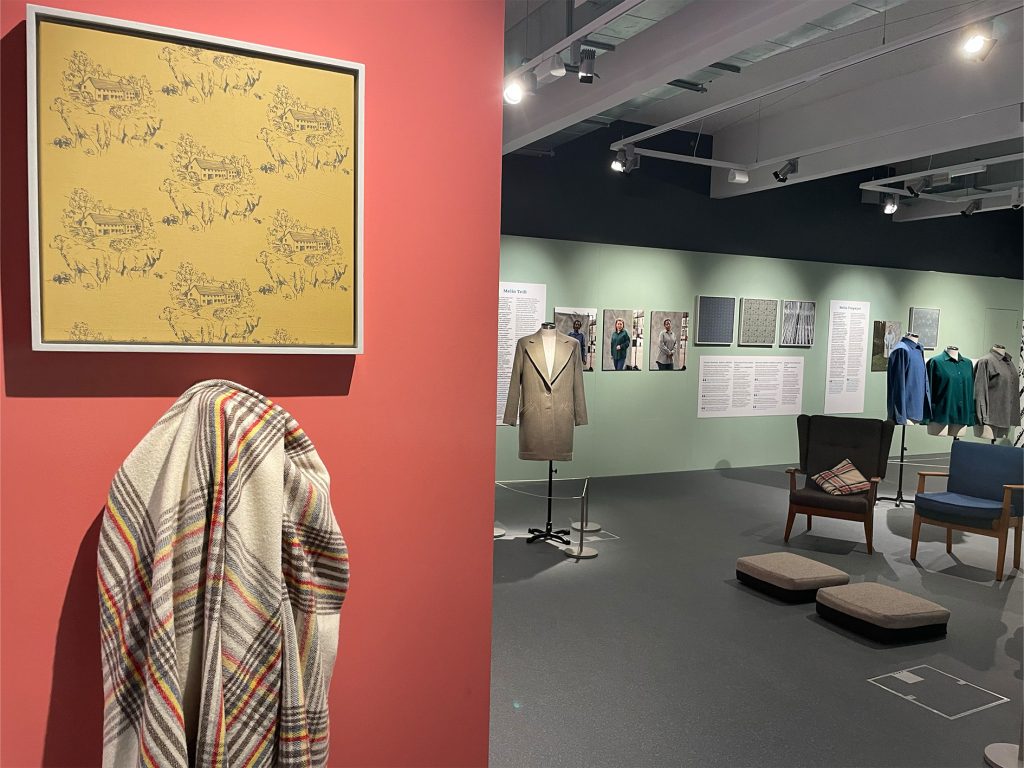

But a Cardiff tailor is celebrating the history of the Welsh wool industry through 10 pieces of clothing in an exhibition at St Fagans museum.

Catherine Davies, 43, owner of Teilwr Bach, has crafted seven jackets and three shirts, using wool from seven different mills across Wales.

“I want to show the beauty of it all and the time that goes into making a garment that is supposed to last forever,” she said.

The display, highlighting how Welsh wool can be spun, woven and crafted into works of art, runs until the end of April.

And for anyone interested in seeing the origins of the high-quality material, Llwyn yr Eos Farm, at the museum, will be open to the public from March 1 to 22 for visitors to see newborn lambs.

Bringing Welsh wool back to life

Three of Ms Davies’ jackets were made using wool from active mills across the country.

- Melin Tregwynt, Pembrokeshire

- Curlew Weavers, Ceredigion

- The Welsh Wool Company, Pembrokeshire

The remaining jackets were made from blankets made at mills that are now closed down, at:

- Ffatri Wlan Gwili Lan, Camarthenshire

- Ffatri Wlan Star, Pembrokeshire

- Melin Wlan Cambria, Powys

- Melin Teifi, Camarthenshire

“I love the idea of things being made locally and knowing exactly where they’ve been woven,” said Ms Davies.

“It brings pride in local skills,” she added.

The lining of each jacket was designed and screen-printed by a different artist at the Printhaus, Canton, to illustrate stages in the wool-to-garment process, including one depicting a wool mill.

The three shirts, were made for the refugee charity Oasis, which also helped craft the garments in a project called Blancot.

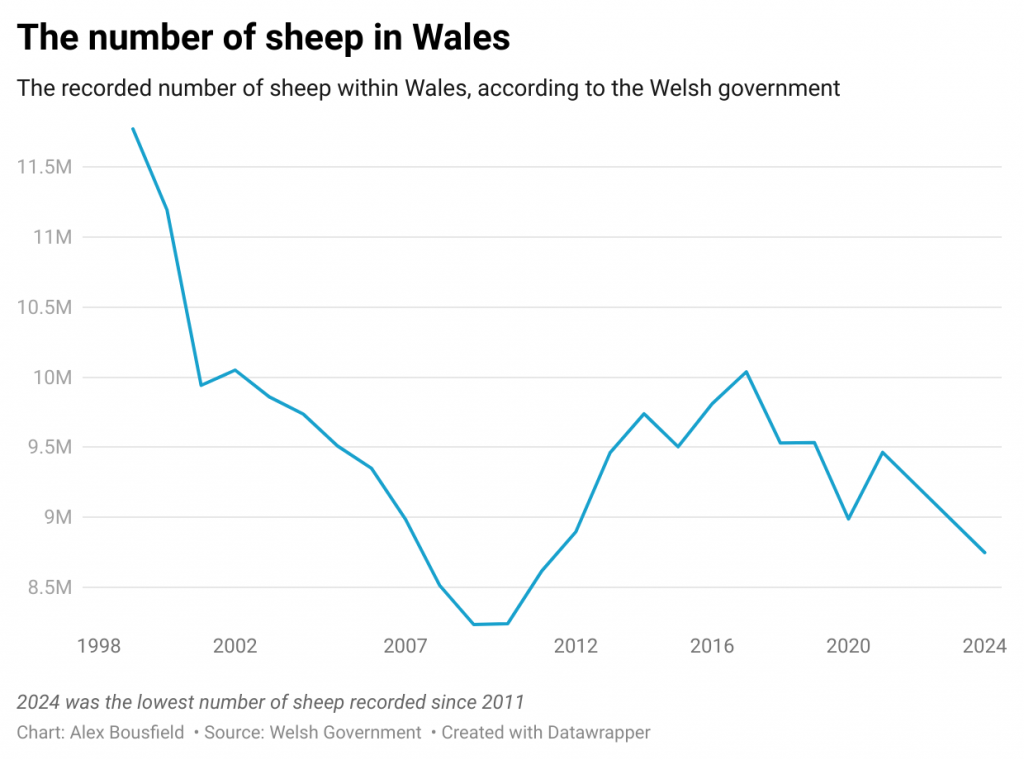

The number of sheep in Wales has decreased to 8.7 million, the lowest number since 2011.

This is due to rising costs of keeping sheep in fertiliser and feed, as well disease preventing lambs being born, according to the National Farmers’ Union.

It is important to support not just Welsh weavers but farmers in getting a better price for the wool, said Ms Davies.

Clare Johns, who created one of the jackets on display using wool from her own flock in Pembrokeshire, said sheep have to be shorn once a year for welfare reasons.

However, a fleece fetches only about 50p each, which barely covers the cost of the shearing, added Ms Johns, 40.

For the last 40 years, farmers have mainly kept sheep for meat or to sell on as breeding ewes and rams, not to produce wool, said Gareth Jones, a British Wool spokesperson.

But, the average price at auction for wool increased by nearly 25% in the last year, indicating a higher demand.

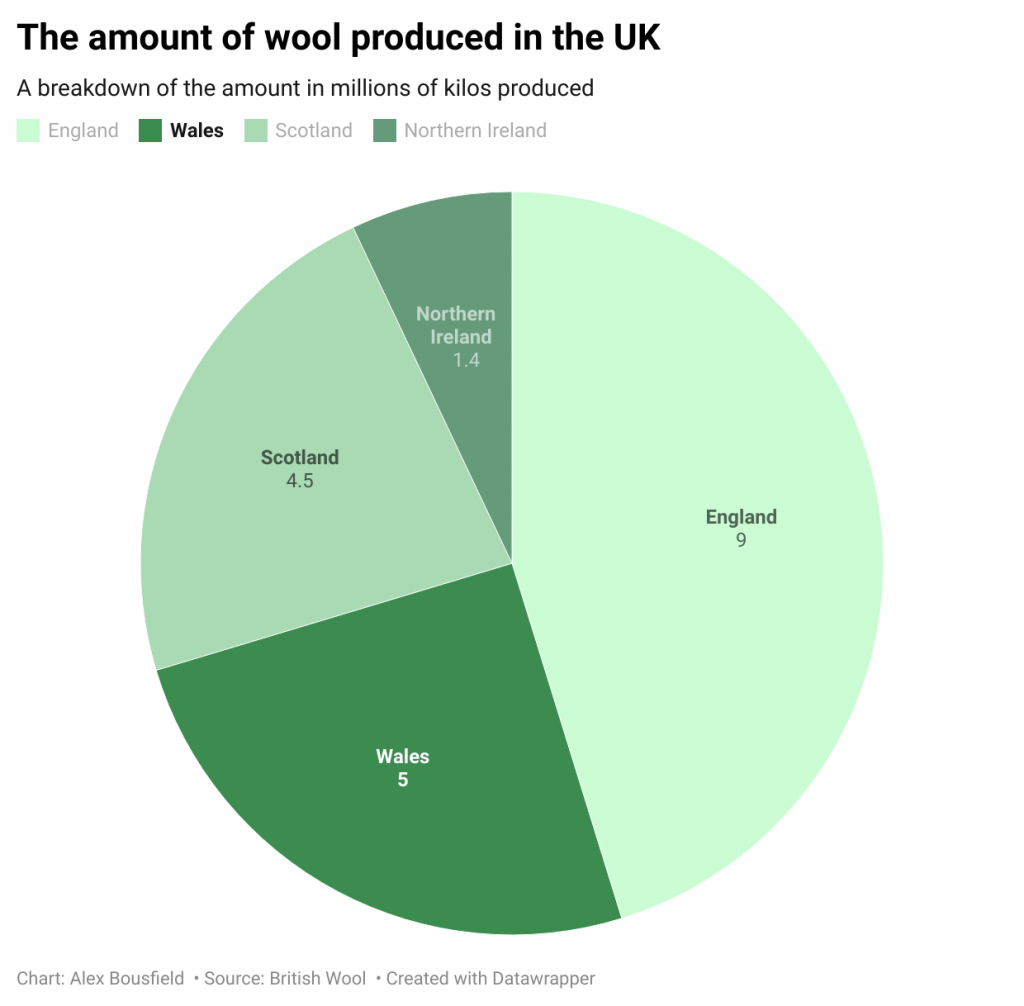

Last year, Wales produced around five million kilos of wool, the second highest amount in the UK, behind England. To make a jacket, requires about five or six fleeces.

“In order for demand for British wool and the price to increase, there needs to be a lifestyle change among us all as consumers.

“If we all make lifestyle choices around wool, investing in those superior quality products made from British wool, this not only supports our sheep farmers but also makes a vital contribution in supporting our environment now, and for future generations,” said Mr Jones.

Read More:

- Rubbish left after the Six Nations

- Running 100 miles in 50 hours

- The choir challenging the stigma of dementia

The benefit of wool

Wool is natural, biodegradable and renewable.

It is also thermo-regulating, because it can insulate in cold weather and be cooling in warm weather and it is breathable.

It also has an anti-bacterial property, which can prevent the build-up of odour.

According to British Wool, 75% of the fibres used globally to make clothes is synthetic and of the rest wool accounts for less than 2%.

Synthetics fabrics require large amounts of water in production and contain microplastics that won’t biodegrade at the end of its life.

Cost

The elephant-sized sheep in the room is the cost attached to producing garments from wool.

“People are starting to choose natural fibres now,” said Ms Davies.

But the cost of having a handmade item that takes months to weave, design, knit and stitch together is much higher than an item that is mass-produced.

Ms Johns estimated that the average cost of a jacket would be around £700.

“It didn’t used to be such an exclusive thing because everyone used to go to the tailors,” said Ms Davies.

Having one item of good quality could last a lifetime and could be repaired multiple times.

“It is something that if everyone did it then the cost would come down,” she added.